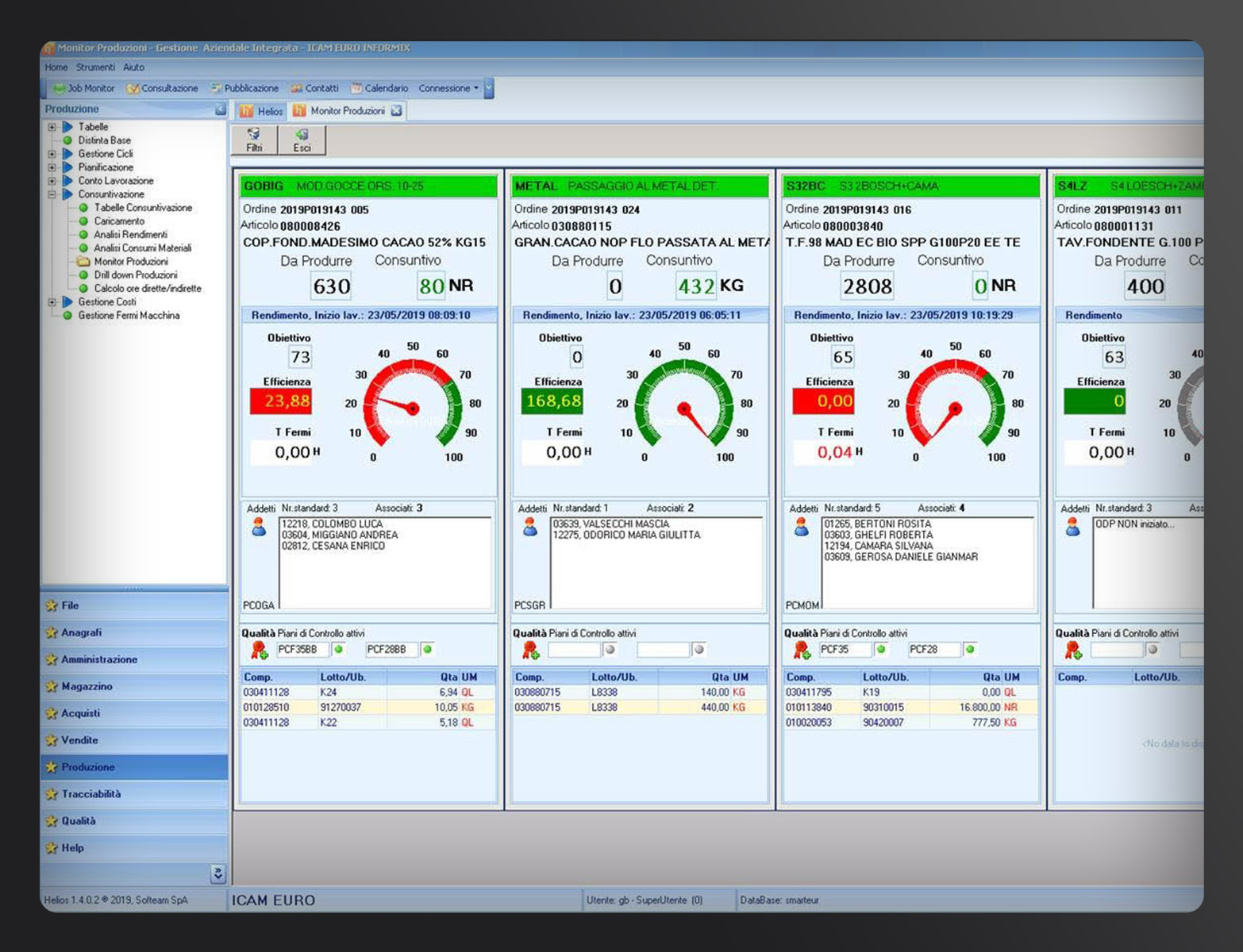

Helios software is also an excellent Manufacturing Execution System.

In fact, thanks to Helios MES functionalities you can follow everything that happens on the plant floor, planning, organizing, and directing the execution of production cycles starting from even very complex bills of materials.

Our MES helps you define the most appropriate models to obtain a product with the best marginalities and the shortest execution time.

Control every step of production, by binding processing to set standards and operational parameters.

Finally, obtain valuable data from the plant floor that you can use to evaluate performance and plan the distributionof your products. Helios software, in its MES module, can in fact communicate with production machinery by interacting both with their PLCs and with IIoT management software such as our Orquestra.

Helios MES thus helps you to control every aspect of production, from planning to execution to analysis of results. Combined with the other components of Softeam’s offering, first and foremost of course with Helios ERP, it then helps you build a complete and fully integrated management system that improves the competitiveness of your company, whatever sector it operates in.